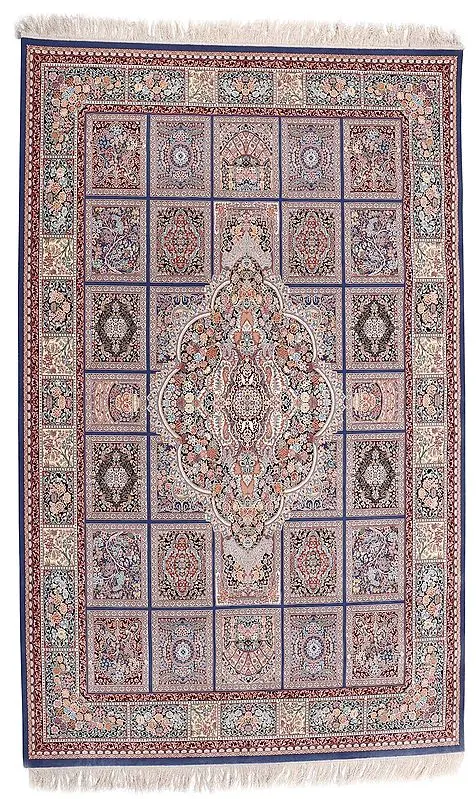

From Fiber to Finery: Unveiling the Craftsmanship Behind Handmade Rug Creation

A carpet serves as a textile floor covering and can be seen in

almost all Asian homes. European nations also are fascinated by their beauty and thus hand-knotted carpets are in great demand all

over the world. A carpet typically consists of an upper layer of

fabric and backing attached to it. Carpets can be made in any

color by using dyed fibers. Different types of motifs and patterns

are fabricated or embroidered on the fabric to beautify the floor.

Indian craftsmen make carpets in such a way that every piece bears

designs with attention to detail. Bright colors and high-quality

fabric are used for their production.

Hand-knotted carpets are made using different types of techniques

such as the Turkish knot (symmetrical), Persian knot

(asymmetrical), Jufti Knot (tied around four warps instead of

two), or Spanish knot (solo warp symmetrical). Common materials

used in the making of the finest carpets are cotton, silk, wool,

and jute.

1. Wool collection and processing

This is the step in the carpet-making process in which the best

quality raw wool is imported or bought from the market. It is then

cleaned and any unwanted particles are removed by washing it

thoroughly. Now the clean wool is dried in the sun for two to

three days.

2. Woolen yarn spinning

Spinning involves a process called carding which is either done

on carding rollers run by hand or with the help of a carding

brush. This wool is now spun into yarn by spinning it on a

spinning wheel, also called a charkha. The thickness of the yarn

depends on the type and quality of the carpet to be made.

3. Dyeing yarn

After the yarn is obtained, it is then dyed into different colors

as per the requirement. The dyed yarn is now allowed to be

sun-dried for at least two days.4. Designing

Designing a carpet is time-consuming and the most important

step. The size, designs/patterns, and colors of the carpet

contribute to the overall look of the carpet. The artisan first

draws the design on paper and then copies it on graph paper.

5. Weaving (Hand-knotting)

Weaving involves two important parts; weft (dyed yarn) and warp

(reeled yarn). The warp yarn is loaded to the vertical loom and

the graph paper containing the carpet sample design is put in

front of the weaver. Each weft yarn is knotted to each warp yarn

by hand. In this way, the whole carpet is weaved and the desired

pattern is obtained.

6. Washing

The carpet is now sent for washing multiple times with water and

cleansing agents to remove dust and dirt from it.

7. Clipping and Binding

Now any protruding knots and extra threads are cut off using

scissors and clippers. Now the craftsmen ensure that all four

sides of the carpet and weaves are locked by stitches so that

the carpet remains intact and strong.

8. Final washing and drying

The carpet is again washed and dried for the last time to make it

appear absolutely neat and clean, ready to be put for sale.

Handmade carpets are often more expensive than those made by

machines. It takes a minimum of six months to complete one carpet

and this elaborate process involves around 20 - 25 artisans

working at the same time.